Hyundai Mobis has unveiled a breakthrough in electric vehicle (EV) technology with the development of its innovative “Pulsating Heat Pipe” (PHP) system, designed to address battery overheating during ultra-fast charging. This cutting-edge material, crafted from aluminum alloy and refrigerant, is strategically positioned between battery cells to enhance thermal management. The technology’s superior heat transfer capabilities aim to reduce EV charging times while maintaining stability, underscoring Hyundai Mobis’ commitment to advancing future mobility solutions. By leveraging this innovation, the company seeks to secure a leading position in battery cooling technology for the competitive EV market.

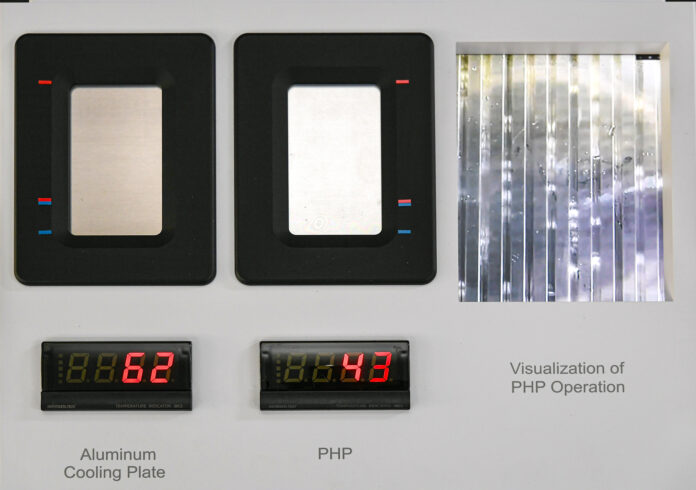

The PHP system represents a significant leap in thermal efficiency compared to conventional aluminum cooling plates, offering over ten times the heat dissipation performance. By using a unique mechanism where refrigerant vibrates and circulates within the heat pipes, the system ensures efficient heat transfer from battery cells to external cooling blocks. This design mitigates overheating risks, even in dynamic environments, without performance degradation due to gravity. Hyundai Mobis’ innovative placement of PHPs between battery cells allows for precise temperature regulation at the module level, ensuring optimal battery performance and longevity.

To streamline production and reduce costs, Hyundai Mobis incorporated advanced press-processing techniques, enabling the mass production of ultra-thin PHPs at just 0.8mm thickness. These thinner and larger-surface-area heat pipes enhance compatibility with vehicle batteries while promoting efficient thermal control. The PHP system’s development aligns with the global push for sustainable mobility, positioning Hyundai Mobis as a frontrunner in EV battery technology. By addressing critical challenges in battery management, the company aims to accelerate the adoption of EVs and contribute to a greener future.