Accelerating Electric Vehicle Safety with Next-Generation Coolants

As electric vehicles (EVs) become increasingly mainstream worldwide, ensuring battery safety and longevity is paramount. Battery thermal management is crucial to prevent overheating, fire risks, and performance degradation that can arise from high-voltage electrical systems. State-of-the-art coolants play a vital role by stabilizing battery temperatures and interacting safely with electrical components. Recent industry developments emphasize not only cooling efficiency but also minimizing electrical conductivity to reduce risks of fluid decomposition or hydrogen generation within battery packs. With global EV markets expanding rapidly, particularly in China—the world’s largest new energy vehicle market—adoption of advanced coolant technologies is critical to meet evolving safety regulations and consumer expectations.

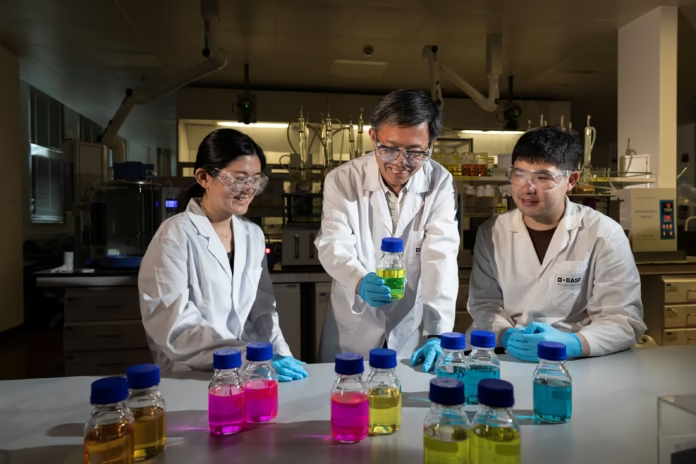

BASF Launches GLYSANTIN® ELECTRIFIED® Low Electrical Conductivity Coolants

In direct response to these escalating demands, BASF has unveiled its GLYSANTIN® ELECTRIFIED® low electrical conductivity coolants (LECCs). Designed to comply with China’s new GB 29743.2-2025 industry standard effective from October 2025, these innovative coolants are formulated specifically for electric vehicle battery systems. By maintaining a low and stable electrical current when near high-voltage components, BASF’s LECCs effectively minimize fluid breakdown and hydrogen gas formation. This significantly reduces risks of battery overheating, fire, or explosions, thereby enhancing vehicle safety. Additionally, GLYSANTIN® ELECTRIFIED® products provide exceptional corrosion protection and compatibility with diverse materials used in battery systems, verified by authoritative testing bodies such as SGS and RATTC.

Strategic Benefits and Market Focus in China and Beyond

BASF’s decision to produce LECCs at its Pudong facility underscores a strategic focus on China’s dynamic EV market, reflecting regionalized innovation and customer-centric manufacturing. The collaboration among BASF, Chinese transport authorities, OEMs, and research institutions highlights a cross-sector initiative to boost EV battery safety through rigorous standards and pioneering technologies. “The initial launch focuses on China with plans to extend globally as demand grows,” said Matthias Lang, BASF Asia Pacific’s Vice President for Fuel and Lubricant Solutions. This strategy leverages BASF’s global research expertise while tailoring solutions to meet specific market regulatory environments and vehicle requirements, paving the way for broader international adoption.

Rooted in a legacy dating back to 1929, BASF’s GLYSANTIN brand has consistently delivered breakthroughs in engine and battery cooling. GLYSANTIN® ELECTRIFIED® represents the forefront in protecting powertrain technologies, including battery and fuel cell thermal regulation. Its formulations align with sustainability goals by supporting low-carbon footprint technologies and circular economy principles. As electric and hybrid drivetrains gain prominence, GLYSANTIN coolants ensure durability and performance for current and future mobility solutions, reinforcing BASF’s commitment to electric vehicle innovation and safety.