Driving the Future of Electromobility

As global demand for electric vehicles (EVs) accelerates, the automotive industry is rapidly transforming. Central to this shift is the evolution of battery technologies and sustainable materials that enhance EV performance, safety, and recyclability. At the forefront of this innovation is BASF, a global chemical leader. At The Battery Show Europe 2025, BASF will demonstrate its wide-ranging solutions that address current challenges in battery efficiency, supply chain transparency, and advanced manufacturing for eMobility. With a focus on sustainability and innovation, BASF is poised to shape the next era of electric mobility.

Battery Innovations and Material Breakthroughs

BASF’s core offering lies in its advanced cathode active materials (CAM), which are crucial for improving EV battery performance, range, and lifespan. The company provides tailored CAM solutions—including NCM, NCA, and LCO chemistries—to top cell manufacturers worldwide. Complementing this, BASF has developed a comprehensive battery recycling portfolio. These services help recover critical raw materials from production waste and end-of-life batteries, significantly reducing reliance on mining and lowering emissions. This circular approach is vital for achieving a sustainable battery supply chain.

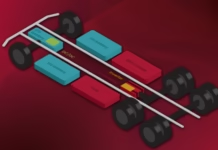

Engineering Plastics and Thermoplastics for Safety and Efficiency

Electric vehicles require components that are lightweight, durable, and safe. BASF offers an extensive range of engineering plastics, such as Ultramid® and Ultradur®, designed for high-voltage connectors and battery modules. These flame-retardant materials provide thermal insulation and structural stability while supporting industry-standard markings and color codes. Innovations like Ultramid® Expand offer lightweight, high-performance solutions for cylindrical cell holders, improving energy density and manufacturing efficiency.

Advanced Adhesives, Coatings, and Digital Tools

BASF’s polyurethane adhesives, including “Debonding on Demand,” support easier battery disassembly for repair and recycling. Their fire-resistant coatings and potting compounds enhance battery safety. Surface treatments like Oxsilan® extend battery component life by preventing corrosion. BASF is also leveraging digital innovation through Path.Era—a scalable digital product passport aligned with Catena-X—to track battery materials across their lifecycle, enhancing traceability, compliance, and circularity.

Pioneering the Future with Next-Gen Solutions

BASF continues to push the limits of lithium-ion and solid-state battery technologies. Its Licity® waterborne binders and OPPANOL® binders enable higher charge capacities, durability, and safety. At the Battery Show Europe 2025, BASF will not only exhibit these solutions but also share insights through expert presentations. These talks will cover digital traceability and sustainable battery adhesives, reinforcing BASF’s commitment to advancing electromobility and cleaner energy systems worldwide.