Introduction to Next-Generation Battery Technologies

In the rapidly evolving landscape of electric vehicles (EVs) and renewable energy storage, battery technology is crucial for performance, safety, and sustainability. Traditional lithium-ion batteries have powered EVs for years but face limitations. Such as relatively low energy density, longer charging times, and safety concerns due to liquid electrolytes. Emerging solid-state battery technology promises to transform this field by overcoming these drawbacks. Solid-state batteries utilize solid electrolytes, which enhance stability, improve energy density, reduce flammability risks, and enable faster charging. Semi-solid-state batteries represent a hybrid innovation, combining the benefits of solid and liquid electrolyte designs. Offering increased safety, higher energy capacity, and environmental advantages—all critical for next-gen electric vehicles, drones, and power tools.

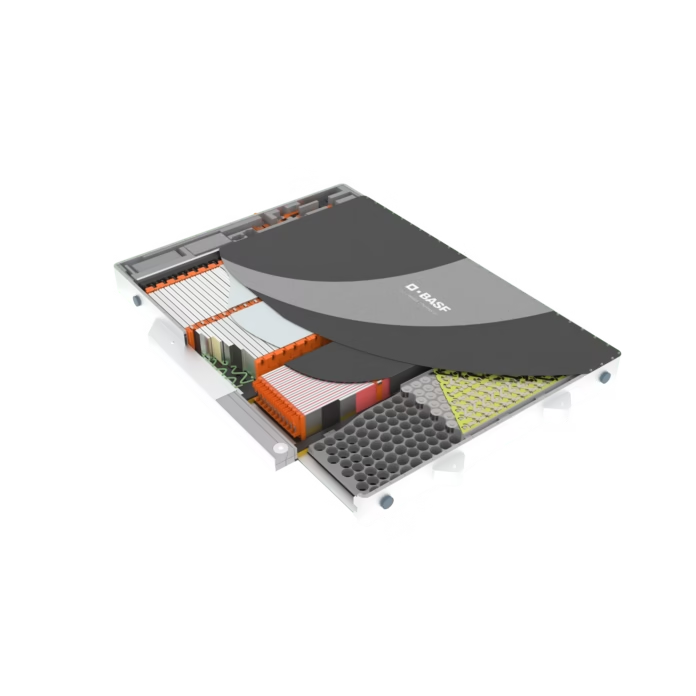

BASF and WeLion’s Strategic Collaboration on Semi-Solid-State Batteries

BASF Battery Materials, through its joint venture BASF Shanshan Battery Materials Co., Ltd. (BSBM), together with Beijing WeLion New Energy Technology Co., Ltd., has made remarkable progress by delivering the first mass-produced cathode active materials (CAM) for semi-solid-state batteries. This achievement highlights the transition from concept to industrial-scale production within just a year since the project’s initiation in August 2024. With over 40 years of pioneering experience in solid-state battery technologies, WeLion focuses on applications in electric vehicles, energy storage systems, drones, and power tools. BASF contributes two decades of expertise in high-performance cathode materials, crucial for solving interface challenges between cathode materials and solid electrolytes that impact energy density and battery longevity.

Key Innovations and Benefits of Semi-Solid-State Batteries

The cathode active material developed by BSBM features an ultra-high Nickel NCM (Nickel Cobalt Manganese) composition with a unique composite coating that addresses interface complications common in solid-state batteries. This coating enhances energy storage capacity by lowering electrical resistance and suppressing detrimental side reactions between the cathode and electrolyte. Consequently, the batteries exhibit improved cycle stability and longer calendar life, addressing two critical hurdles for commercial solid-state battery adoption. Such enhancements translate into more extended driving ranges, faster charging capabilities, and safer EV operations—key improvements that meet rising market demands for higher performance and safety standards in the new energy industry.

Impact on Electric Vehicle Applications and Industry Advancement

Electric vehicles stand to benefit immensely from semi-solid-state battery technology. These batteries offer a compelling combination of increased energy density—potentially doubling that of conventional lithium-ion cells—and enhanced safety, reducing risks of leakage or fire associated with liquid electrolytes. Moreover, the design allows EV manufacturers to produce lighter, more compact battery packs, enabling longer range vehicles with faster recharge times. WeLion’s experience with semi-solid-state cells, integrating both solid and liquid electrolyte traits, positions it as a leader driving the stability and scalability of this innovative battery technology. The collaboration with BASF reinforces global efforts to commercialize safer, more efficient batteries that can accelerate the adoption of electric vehicles while supporting other sectors like drones and energy storage solutions.

Future Outlook and Continued Innovation

The delivery of pioneering cathode materials marks a strategic milestone for both BASF and WeLion New Energy, reflecting their shared commitment to pushing the boundaries of battery technology. Both companies emphasize further deepening cooperation to address remaining technical challenges and to accelerate industrialization of solid-state batteries on a global scale. As the battery market moves toward hybrid and fully solid-state solutions, advances in materials science and manufacturing processes will play a decisive role. Semi-solid-state batteries, exemplified by this collaboration, offer a pragmatic and economically viable bridge to widespread adoption of next-generation energy storage technologies. The progress made today will pave the way for safer, more powerful electric vehicles and renewable energy systems in the near future.