CeCaS Enables Realistic Simulations

Technical University of Munich researchers developed CeCaS. This centralized software architecture processes vast sensor data for autonomous vehicles. Live inputs flow from lidar, radar, and cameras. Data also fuses from nearby vehicles and infrastructure like overhead gantries. Therefore, vehicles evaluate information ad hoc. Funded by German BMFTR, CeCaS targets 2033 models. It ensures safe travel in any weather or traffic. Moreover, partners from automotive and chip industries collaborated over three years.

Graphics Chips Generate Scenarios

CeCaS creates simulation environments with powerful graphics chips. Teams produce diverse conditions like rain or heavy traffic. Vehicles train virtually first. Then, they store knowledge onboard. Furthermore, an open-source platform shares scenarios for industry and research. This tests edge cases safely. As a result, autonomous systems handle real-world surprises effectively.

Open-Source Boosts Collaboration

Industry users access CeCaS simulations freely. Researchers refine models quickly. For example, past accident data recreates failures. No physical risks occur. Thus, development accelerates. Electric vehicle applications benefit in fleets and robotaxis.

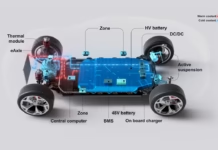

Cost Reductions Through Centralization

Traditional vehicles use over 100 control units. CeCaS swaps them for versatile computers. Cables disappear. Installation simplifies greatly. Costs plummet. Moreover, software upgrades add functions easily. Customers customize like smartphone apps. For instance, new safety features deploy over-the-air. Therefore, makers stay competitive.

Simplified Wiring Saves Resources

Fewer components mean lighter vehicles. Battery life extends. Production scales faster. Meanwhile, test rigs validate everything. Digital twins simulate live scenarios. No injuries happen during trials. Hence, reliability soars for autonomous driving.

Digital Twins Power Test Bench Validation

TUM’s rig secures vehicles by all axles. It tests brakes, assistance, and emergency systems. Digital twins introduce virtual hazards. Teams practice responses. Past crashes replay accurately. For example, semi-autonomous failures become training data. Thus, systems improve iteratively.

Bridges Sim and Reality

Bench testing mirrors road conditions. Sensors react identically. Software refines in loops. As a result, deployment risks drop. Electric vehicle applications in trucks gain precision.

AI Generates Software Effortlessly

AI processes textual specifications. Models check for consistency first. Then, code generates in seconds. CeCaS requires full architecture compatibility. Professor Knoll emphasizes software-defined vehicles. Innovation speeds up dramatically. For instance, generative AI verifies completeness. No contradictions slip through.

Accelerates Development Cycles

Software creation becomes effortless. Teams focus on high-level design. Updates roll out rapidly. Therefore, vehicles evolve post-sale. Competition intensifies in autonomous markets. Overall, CeCaS positions future cars as platforms. They adapt via code, not hardware.