Revolutionary Dry-Coating Technology for Batteries

The Fraunhofer Institute for Material and Beam Technology IWS officially launched its DRYplatform on November 3, 2025. This is as a flagship infrastructure to accelerate dry electrode coating research and industrialization. At the core of this platform is the patented Dry Transfer Electrode Coating process (DRYtraec), a solvent-free, roll-to-roll dry coating technique. Traditional wet-coating methods that require energy-intensive drying steps and solvents. However DRYtraec directly transfers dry films to substrates, reducing both environmental impact and production costs. Solvent-free and resource-efficient, the process works across numerous battery types. Including lithium-ion, solid-state, sodium-ion, and lithium-sulfur systems, and is available for licensing by industrial partners.

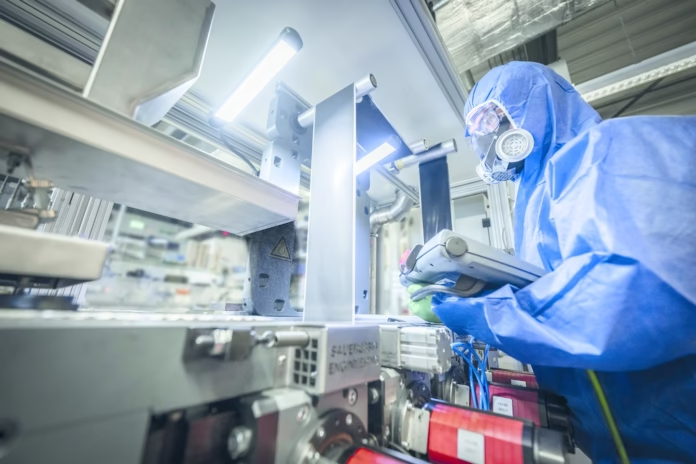

Integrated Infrastructure Enabling Scalable Innovation

DRYplatform offers a flexible dry-air multi-chamber system with precise humidity control, high-intensity mixers for powder preparation, and connected analytics for inline and offline data integration. Basically this allows rapid development and scaling from laboratory concepts to near-industrial demonstrations. Cell testing, post-compaction, and finishing units complement the coating process. While a shared digital infrastructure enables comprehensive analysis of material-process-property relationships. This setup accelerates technology transfer from science to industry. The €3.7 million project, funded by the German Federal Ministry of Education and Research, is strategically important for Germany’s battery industry competitiveness and innovation capacity.

Collaboration, Supply Chain Resilience, and Expertise

Building DRYplatform involved overcoming supply chain challenges and energy cost increases by adopting a low-cost, multi-chamber dry-air design. Experts across disciplines—chemists, process engineers, mechanical engineers, and analytics specialists—collaborated closely to create a versatile, reliable research environment. This interdisciplinary teamwork facilitates fast, reliable solutions to complex questions obtained from experiments, strengthening the facility’s position as a premier European research hub for dry battery electrode coating.

Industry-wide Benefits and Strategic Importance

DRYplatform supports stakeholders across the battery value chain. Powder suppliers can validate formulations, equipment manufacturers optimize processes, and cell producers evaluate electrochemical performance under realistic conditions. Furthermore, automotive and aerospace sectors gain a foundation for advanced product development. This infrastructure also helps German industry reduce dependency on costly imports and maintain a competitive edge in the global e-mobility market. The platform’s close integration with Fraunhofer Research Fabrication Battery Cell (FFB) enables a seamless pipeline from cutting-edge research to pilot-scale manufacturing scheduled for late 2025.

Outlook: Transforming Battery Manufacturing for the Future

Fraunhofer’s DRYplatform marks a significant leap in battery manufacturing innovation by enabling scalable, sustainable evaluations of dry-coating technology. Its ability to efficiently assess new electrochemical concepts early enhances technology readiness and decision-making on incorporating dry coating alongside or instead of wet processes. This transition will decisively influence which battery cell technologies dominate the market over the next decade, shaping cleaner, more cost-effective EV production. Through the DRY Coating Forum and industry partnership, the platform fosters accelerated knowledge exchange and cooperation, setting a new standard for battery electrode manufacturing worldwide.