The Evolving Needs of Electric Vehicle Safety

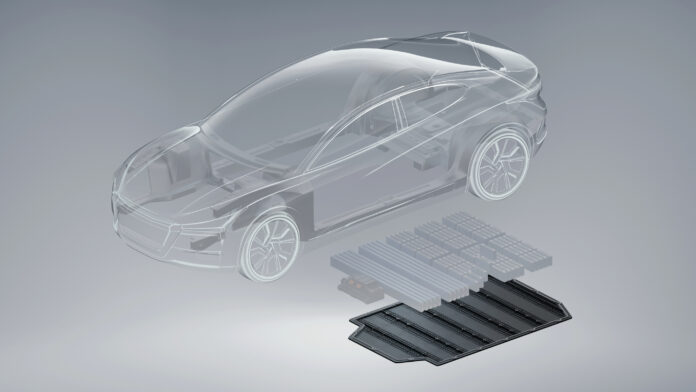

Batteries are central to EV performance, and their protection is crucial in the event of impact, fire, or environmental exposure. This shift in mobility calls for new materials and technologies that offer strong yet lightweight shielding. Responding to these challenges, Autoneum has introduced a thermoplastic composite impact protection plate. This solution not only addresses safety but also contributes to vehicle efficiency and sustainability.

Autoneum’s Lightweight Composite Plate: A Dual-Purpose Solution

Autoneum’s new impact protection plate is designed specifically for the demands of electric vehicles. Made from advanced thermoplastic composite material, it offers robust protection against impact, fire, and corrosion. What sets it apart is its dual functionality. While delivering exceptional impact resistance, the plate also acts as a thermal insulator. This insulation helps stabilize battery temperature, ultimately extending the vehicle’s driving range. By replacing heavier metal parts, it supports weight reduction without compromising strength.

Cutting-Edge Technology: Long-Fiber Thermoplastics in Action

The impact protection plate utilizes long-fiber thermoplastic (LFT) technology, which provides high design flexibility and enhances structural performance. Reinforcements built into the material ensure maximum rigidity even under repeated stress from road debris and stone impacts. Unlike traditional solutions, this composite does not deform or lose strength over time. The design also enables waste-free manufacturing, making it both efficient and eco-friendly. These innovations have been validated by simulations and tested by multiple European automotive manufacturers.

A Leap Forward in EV Battery Protection and Efficiency

Autoneum’s innovation highlights a new standard in underbody shielding and battery protection. By integrating thermal management with mechanical safety, the composite plate plays a key role in the overall energy efficiency of EVs. Its ability to withstand extreme conditions while maintaining structural integrity makes it an ideal solution for modern electric vehicles. As the automotive industry accelerates toward full electrification, such technologies are vital in shaping the next generation of safe and efficient transportation.