Regional Collaboration Driving Innovation in Electromobility

BMW Group‘s largest engine plant in Steyr collaborates closely with voestalpine Stahl GmbH of Linz to produce advanced electric motors for BMW’s New Class electric vehicles. This partnership combines regional expertise and innovative technology, underlining Austria’s role in shaping the future of premium electric mobility. By leveraging local resources and reducing transportation emissions, this collaboration advances the development of efficient, high-performance electric drivetrains.

Technical Advantages of voestalpine’s Electrical Steel

At the heart of this innovation is voestalpine’s newly developed electrical steel, designed specifically to meet the demands of modern electric motors. This ultra-thin electrical steel boasts exceptional magnetic properties and is coated with state-of-the-art technology to minimize energy losses during motor operation. These improvements reduce heat generation, increase efficiency, and expand the driving range of electric vehicles. Additionally, the steel’s strength and high permeability allow for lighter electric motors that contribute to overall vehicle weight reduction and better energy consumption.

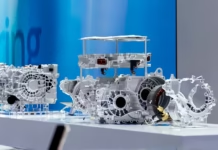

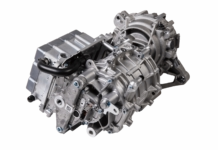

Gen6 Electric Motor: Advancing BMW’s Powertrain Technology

The sixth-generation (Gen6) electric motor produced at the Steyr plant represents a leap forward in electric drivetrain technology. Incorporating 800-volt architecture, it improves battery and motor efficiency compared to the previous generation. The motor uses a current-excited synchronous machine (SSM) design, eliminating the need for rare-earth magnets. Integration of silicon carbide (SiC) technology in the inverter enhances performance and reduces noise. All components, including the rotor, stator, gearbox, and inverter, are manufactured in-house, ensuring high quality and precision.

Manufacturing Excellence and Sustainability in Upper Austria

The Steyr plant’s advanced manufacturing processes transform voestalpine’s electrical steel strip into laminated cores that form the motor’s core components. This localized production minimizes freight-related emissions and helps preserve regional economic value. The collaboration highlights how combining resource-efficient production standards with cutting-edge materials supports Austria’s competitiveness in electromobility. An investment of around €1 billion aims to scale annual production of Gen6 electric motors up to 600,000 units by 2028.

Impact on Electric Vehicle Applications

This innovative partnership directly influences the performance and sustainability of BMW’s electric vehicles. The efficient electrical steel and highly integrated motor design improve torque and acceleration, extend driving range, and reduce energy consumption. These enhancements benefit both passenger vehicles and commercial EV applications as the automotive industry accelerates its transition from fossil fuels to electric propulsion technologies.

A Model for the Future of Electromobility

The success of this partnership between two premium Upper Austrian companies illustrates the power of regional innovation and cooperation. By integrating high-performance materials with advanced motor technology, BMW and voestalpine are setting new standards for electric vehicle drivetrains. Their collaborative approach not only drives technological progress but also reinforces sustainable and economically responsible production practices. This model offers valuable insights for the global automotive industry’s electrification journey.