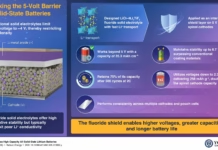

Electric vehicles (EVs) are reshaping the automotive industry, driven by rapid advances in battery technology. A pivotal development in this space is the emergence of all-solid-state batteries (ASSBs). That’s promising higher energy density, enhanced safety, and faster charging compared to conventional lithium-ion batteries. These advances aim to boost EV performance while reducing costs and environmental burdens. Industry leaders like Nissan are investing heavily in next-generation battery solutions to maintain a competitive edge and accelerate the global shift toward sustainable transportation.

Nissan and LiCAP’s Partnership: A Strategic Move

In early 2025, Nissan Motor Co., Ltd. announced its strategic partnership with U.S.-based LiCAP Technologies, Inc. The collaboration focuses on developing production process technologies specifically for the cathode electrodes of ASSBs. This partnership targets a transformative manufacturing method known as the dry electrode process. Traditional electrode production relies on solvents, which require lengthy drying phases and complex solvent recovery systems, inflating both costs and environmental impacts. Conversely, LiCAP’s proprietary Activated Dry Electrode® technology eliminates these drawbacks by enabling efficient, solvent-free production. This alliance accelerates Nissan’s roadmap toward commercializing advanced ASSBs by 2028, embodying a significant leap forward in EV battery technology.

The Importance of Dry Electrode Production for EV Batteries

Dry electrode production represents a critical breakthrough in ASSB manufacturing. This technique reduces the need for energy-intensive drying steps and minimizes hazardous solvent use, making production cleaner and more sustainable. Yet, scaling this process for mass production poses challenges, mainly balancing production efficiency with battery performance. LiCAP’s technology addresses these challenges by offering high efficiency and robust electrode quality, vital for meeting the increasing demand for electric vehicles worldwide. By integrating this technology, Nissan aims to streamline manufacturing workflows and lower costs, key objectives for broader EV adoption and sustainability.

Nissan’s Vision: From Innovation to Market Launch

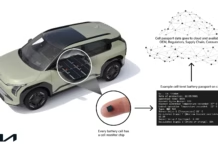

Nissan has already made significant progress by establishing a pilot line for all-solid-state batteries in January 2025. This step underscores Nissan’s commitment to developing in-house battery technologies that will power future EV models. The goal is to commercialize EVs equipped with high-performance, cost-effective ASSBs by the fiscal year 2028. This agenda highlights Nissan’s focus on not only technological innovation but also on practical and environmentally conscious production processes. The collaboration with LiCAP enhances Nissan’s capability to meet these targets efficiently, positioning the company as a front-runner in automotive innovation with tangible benefits for consumers and the planet.

Electric Vehicle Applications and Future Prospects

The partnership between Nissan and LiCAP Technologies exemplifies a forward-thinking approach to overcoming the challenges of battery production for electric vehicles. By developing dry electrode production methods for ASSBs, Nissan is paving the way for lighter, safer, and more sustainable electric cars. These innovations promise to accelerate the global transition to clean transportation while reducing manufacturing costs and environmental impact. As ASSB technology matures, its applications will expand beyond EVs, contributing to a broader energy transition and smarter mobility solutions worldwide.