European Push for Advanced Electric Vehicle Battery Packs

Electric vehicles (EVs) are key to sustainable transportation, but their success depends heavily on battery performance, safety, and cost. Recognizing this, the Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University leads the RESiLiTE project, a cutting-edge EU initiative funded with roughly €6.2 million. The project aims to improve electric vehicle battery packs by boosting energy density, increasing efficiency, enhancing safety, and expanding operating temperature ranges. These innovations seek to lower lifetime costs while improving sustainability and reliability. Notably, this research may extend beyond cars to electrify the aviation sector, underscoring the wide impact of these advancements.

Innovative Battery Pack Design and Materials

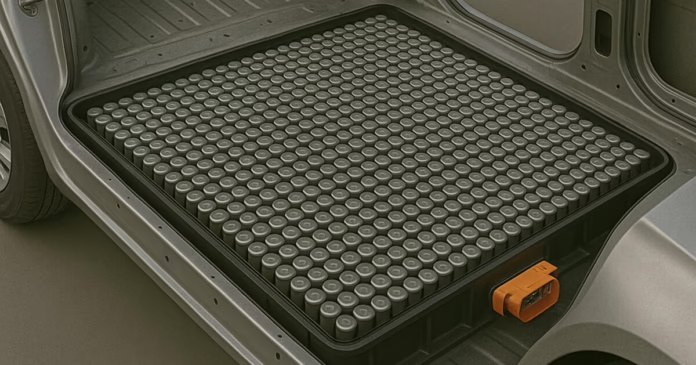

The RESiLiTE project centers around cylindrical cells arranged tightly in thermoplastic housings using a cell-to-pack (C2P) architecture, which eliminates the need for conventional potting materials. This approach achieves a targeted energy density of 220 to 230 Wh/kg at the pack level—over 14% above current technologies. The housing is crafted from recycled fiber-reinforced thermoplastic materials, offering both lightweight protection and thermal insulation. This insulating effect especially benefits cold environment performance by extending battery life before active heating is necessary. Moreover, integrated indirect cooling in the cell holders supports rapid charging and discharging rates over 4.5 C, while fire safety is enhanced by a soft ventilation system and fire-retardant nanomaterials embedded in the structure.

AI-Enhanced Thermal Management and Safety Diagnostics

To guarantee safety and optimize efficiency, RESiLiTE incorporates advanced diagnostic tools like electrochemical impedance spectroscopy (EIS) alongside neural network-based thermal management algorithms. These technologies continuously monitor battery health, predict states of charge and health, and adapt thermal controls peacefully under different real-world scenarios. Such smart management increases energy efficiency and battery lifespan, while providing redundancy for safer operation. The integration of these next-generation diagnostics and controls reflects a holistic push toward resilient, sustainable battery systems designed for the demanding electric vehicle context.

Collaborative Effort with Pan-European Partners

RESiLiTE unites academic, industrial, and research organizations from six European countries: Germany, Austria, Spain, Portugal, Slovenia, and Turkey. The consortium features key players such as Infineon Austria, Fraunhofer Institutes, and the Turkish electric car maker Togg, coordinated by Kautex Textron. This wide-ranging collaboration combines expertise in material science, battery engineering, and manufacturing to accelerate the deployment of these innovative battery packs. Running from mid-2025 to 2028, the project exemplifies strategic EU investment in technologies crucial for the future of electric mobility and clean aviation.

This ambitious project poised to reshape electric vehicle battery technology highlights ongoing advancements required to meet the rigorous demands of e-mobility with safer, lighter, more efficient, and longer-lasting batteries.