Paul Scherrer Institute (PSI) scientists have pioneered a game-changing manufacturing method for all-solid-state batteries. This innovation targets lithium metal anodes and argyrodite electrolytes, boosting safety and energy density for electric vehicles. Moreover, it addresses key hurdles like dendrite growth and interface issues head-on.

Why All-Solid-State Batteries Matter

All-solid-state batteries replace risky liquid electrolytes with solid ones, slashing fire hazards in electromobility. For instance, they enable thinner lithium metal anodes, which pack more energy than graphite alternatives in today’s lithium-ion packs. Consequently, EVs could double their range without added weight.

Safer Than Lithium-Ion Counterparts

Traditional batteries rely on flammable liquids, sparking recalls like those from Chevrolet Bolt in 2021. In contrast, solid-state designs eliminate this danger. Therefore, they suit high-demand uses, from smartphones to grid storage, where reliability counts most.

Tackling Dendrite Formation

Lithium dendrites—needle-like growths—pierce electrolytes, causing shorts and failures. PSI’s team, led by Mario El Kazzi, faced this in argyrodite Li₆PS₅Cl, a sulfide material prized for its ion conductivity. Previously, high-pressure compression left voids; hot sintering over 400°C degraded it. So, researchers sought balance.

The Densification Challenge

Argyrodite powders resist packing tightly, inviting dendrite paths. High heat fuses particles but risks chemical breakdown. Meanwhile, room-temperature pressing yields porous results. Thus, PSI innovated to merge efficiency with stability.

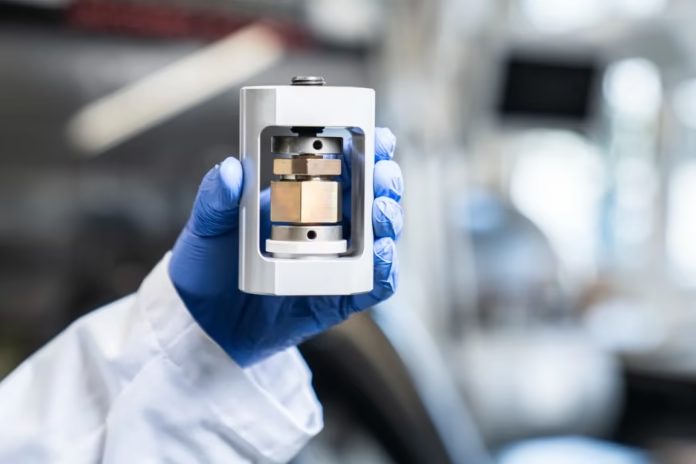

PSI’s Breakthrough Process

El Kazzi’s group combined mild sintering at 80°C with moderate pressure. This rearranges particles into a dense structure, sealing voids without harm. Particles bond closely, ensuring swift lithium-ion flow for fast charging. However, they didn’t stop there—interface stability demanded more.

Lithium Fluoride Coating Magic

Next, they evaporated a 65-nanometer LiF layer onto the lithium anode. This ultrathin shield serves dual roles. First, it blocks electrochemical reactions that spawn “dead lithium.” Second, it halts dendrite incursions physically. As a result, the anode-electrolyte junction thrives under stress.

Lab-Tested Endurance

Button cells endured 1,500 cycles at high voltage, retaining 75% capacity. Lead author Jinsong Zhang calls this top-tier performance. Lithium ions shuttled reliably from cathode to anode, outpacing many rivals. Furthermore, low-temperature processing cuts energy costs, aiding scalability.

Path to Market Readiness

This duo—gentle sintering plus LiF passivation—conquers dendrites and instability. Unlike energy-hungry methods, it runs cool and cheap. El Kazzi envisions industrial tweaks for argyrodite batteries soon. Meanwhile, it aligns with EV giants like Toyota, who eye solid-state for 2027 launches.

Broader EV Industry Impact

Solid-state advances accelerate beyond PSI. For example, Samsung SDI hit 900Wh/L densities in 2025 pilots, nearing gasoline parity. QuantumScape’s separator tech curbs dendrites similarly, partnering with Volkswagen. Thus, PSI’s work complements a surge: EV sales topped 18 million globally in 2025, per IEA data. Moreover, safer batteries ease consumer fears, spurring adoption.

Economic and Eco Wins

Low-temp production slashes carbon footprints versus sintering kilns. Costs drop as scale rises—projections show solid-state packs at $60/kWh by 2030, under BloombergNEF estimates. Therefore, automakers gain affordable range kings. Drivers benefit too: imagine 600-mile EVs charging in 10 minutes.

Future Outlook for Electromobility

PSI’s method positions all-solid-state batteries for prime time. It solves pain points that stalled progress for years. As competitors like Solid Power test sulfide stacks, integration speeds up. Consequently, 2030 could see EVs dominating roads with unbreakable power.

Hurdles Remaining

Scale-up tests loom large—pilot lines must match lab purity. Yet, PSI’s efficiency hints at viability. For instance, pairing with NMC cathodes could hit 500Wh/kg. In turn, this fuels mass-market EVs, cutting oil dependence.

This process not only stabilizes batteries but transforms them. Researchers pave a practical road to superior energy storage. Electric mobility surges forward, safer and stronger.