Sodium-ion batteries emerge as a sustainable rival to lithium-ion tech. Researchers at Germany’s Federal Institute for Materials Research and Testing (BAM) unveiled a game-changing Sodium-ion core-shell anode design. This innovation shields the anode’s porous core, slashing storage losses and boosting overall performance. Moreover, it leverages cheap, eco-friendly materials to make sodium-ion batteries more viable for mass markets.

Challenges in Sodium-Ion Battery Development

Sodium-ion batteries promise abundance and lower costs compared to lithium-ion counterparts. However, they face a major hurdle: high irreversible capacity loss during the initial charge cycle. Electrolyte molecules break down on the hard carbon anode, invading its pores and forming a solid electrolyte interphase (SEI) film. This film consumes sodium ions, reducing storable capacity right from the start.

Traditional lithium-ion batteries avoid this issue easily. Their graphite anodes form a stable SEI quickly, hitting over 90% efficiency. Sodium ions, however, don’t intercalate well into graphite. Thus, developers turn to hard carbon anodes, which offer high capacity but suffer 18% efficiency without protection. Consequently, these losses slow commercialization.

Transitioning to solutions, BAM experts identified the core problem. Materials excelling in storage often falter in SEI formation. For instance, porous hard carbons hold more sodium but invite more electrolyte decomposition. This trade-off demanded a fresh approach.

Innovative Core-Shell Anode Design Explained

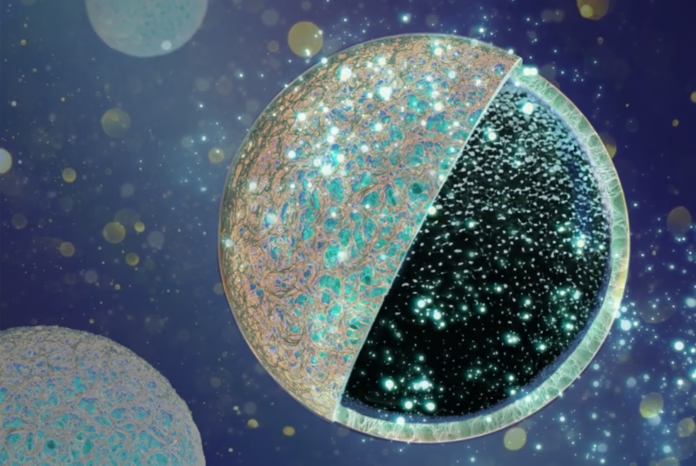

BAM’s team crafted a dual-layer anode: a porous hard carbon core for sodium storage, wrapped in a thin protective shell. This shell acts like a selective filter. It lets sodium ions pass freely while blocking harmful electrolyte molecules. As a result, the core stays intact, preserving capacity over countless cycles.

The design draws from activated carbon, abundant and non-toxic. Tim-Patrick Fellinger, a BAM energy materials specialist, noted that no single material balances storage and efficiency perfectly. Instead, they separated these functions. The shell handles SEI formation efficiently; the core maximizes sodium hosting. Published in Angewandte Chemie, this work marks a pivotal step forward.

Furthermore, this mirrors broader trends in battery engineering. Similar Sodium-ion core-shell strategies appear in lithium-sulfur batteries to trap polysulfides. In sodium-ion contexts, such designs align with efforts to rival lithium’s dominance. Early tests show 82% initial efficiency—a quadrupling from uncoated versions.

How the Filter Shell Works

The shell’s magic lies in its molecular sieve effect. During formation, it builds a stable SEI using minimal sodium. Electrolyte decomposition stops early, unlike in bare hard carbons. Sodium ions then shuttle efficiently into the core’s sponge-like structure. This setup endures hundreds of cycles without degradation.

Performance Gains and Efficiency Breakthroughs

The new anode delivers simultaneous wins in efficiency and capacity. Uncoated hard carbons waste nearly 20% of capacity on SEI buildup. BAM’s coated version cuts this dramatically, achieving 82% Coulombic efficiency on first charge. Paul Appel from the team predicts even higher marks soon.

This progress shifts focus from cathodes, where limits near. Anodes offer untapped potential through advanced materials. For example, doping or nanostructuring could push capacities beyond 350 mAh/g. Meanwhile, the design’s simplicity aids scalability. Manufacturers can coat existing hard carbon via chemical vapor deposition or pyrolysis.

In comparison, leading sodium-ion prototypes from CATL and Faradion hover around 75-80% initial efficiency. BAM’s approach surpasses them, using no rare metals. Thus, it supports grid storage and EVs, where cost trumps energy density.

Future Development at Berlin Battery Lab

BAM advances this tech at the Berlin Battery Lab (BBL). This hub unites BAM, Helmholtz Zentrum Berlin, and Humboldt University. Together, they fast-track lab innovations to industry. BBL’s facilities test full cells under real-world stresses like fast charging.

Funding from Germany’s Federal Ministry of Research powers projects like DialySorb and NMR-Batt. These emphasize NMR spectroscopy for SEI insights. Industry partners eye commercialization by 2028. Meanwhile, global sodium-ion capacity grows; China leads with 10 GWh pilots in 2025.

Market Implications for Sustainable Batteries

Sodium-ion batteries shine for stationary storage. Their tolerance for deep discharge suits renewables integration. Unlike lithium, sodium sources abound—no supply chain woes. Pair this anode with layered oxide cathodes, and cells hit 160 Wh/kg. EVs may follow for urban fleets.

Challenges persist, like voltage gaps versus lithium. Yet, innovations like BAM’s close the gap. Analysts forecast sodium-ion at 10% of grid batteries by 2030. This core-shell design accelerates that timeline. Ultimately, it democratizes energy storage, curbing reliance on scarce lithium.