The Critical Role of Thermal Management in EVs

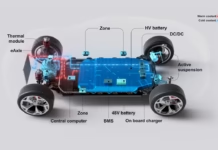

Electric vehicles (EVs) rely heavily on thermal management to perform efficiently and safely. Without proper temperature control, components overheat, leading to reduced lifespan and power limitations. Traditional cooling systems rely on hardware sensors, which struggle to access the motor’s hottest, most compact regions. To overcome this, automakers are turning to artificial intelligence. AI-based thermal monitoring offers a new level of control—one that is smarter, more efficient, and requires less hardware. ZF is now at the forefront of this shift with its latest innovation: TempAI. This breakthrough technology delivers a smarter, faster way to manage heat in electric drivetrains.

TempAI – AI-Powered Precision for EV Temperature Control

ZF’s TempAI redefines how electric motor temperature is measured. Unlike traditional methods, TempAI uses AI algorithms to interpret existing data and predict internal motor temperatures with over 15% more accuracy. What’s revolutionary is that it does this without adding any new sensors or hardware. Instead, the system builds self-learning models from data already collected in the test environment. These models are light on processing needs and easily integrate into existing electric vehicle platforms, making them ideal for series production.

Boosting Power and Efficiency in Real-World Driving

Thanks to more precise temperature forecasting, TempAI pushes electric motors closer to their thermal limits without risking damage. This translates into real-world benefits: up to 6% more peak power and enhanced efficiency in the WLTP cycle. Even in demanding scenarios—like track driving—energy consumption drops by up to 18%. For both everyday users and performance enthusiasts, this means longer range, better acceleration, and smarter energy use. TempAI doesn’t just optimize performance; it makes electric mobility more practical and powerful.

Environmental Gains and Shorter Development Cycles

Beyond performance, TempAI supports sustainability. More efficient thermal control allows engineers to reduce the need for heavy rare earth materials—often required in electric motor construction. Additionally, what once took engineers months to model manually can now be achieved in days with AI. This not only slashes development time but also brings down costs. Using AI to predict and manage internal motor temperatures gives manufacturers a deeper understanding of component behavior, even when direct measurement is impossible or expensive.

Final Thoughts – A Smarter Future for Electric Mobility

ZF’s TempAI is a significant step forward for electric vehicle applications. By harnessing AI to tackle one of the most complex challenges in e-motor design—thermal management—the company has unlocked new levels of efficiency, power, and sustainability. This innovation reflects a broader trend across the EV sector: smarter software, less reliance on hardware, and more performance gains from intelligent design. TempAI isn’t just a tool; it’s a gateway to more reliable and efficient electric transportation.