Electric Vehicle Battery Innovation

Electric vehicles (EVs) are transforming the automotive industry, with battery technology at the heart of this revolution. High-voltage batteries are crucial for an EV’s performance, affecting energy density, charging speed, and driving range. Leading manufacturers like BMW Group are pushing the boundaries of battery technology, particularly with their sixth-generation (Gen6) eDrive batteries. These advancements enable longer ranges and faster charging, key factors in widespread EV adoption. Modern battery production integrates cutting-edge data analytics and AI to streamline manufacturing and ensure quality. BMW’s global strategy includes developing five new assembly sites and pilot plants to pioneer this sophisticated battery production process.

The Integration of Data Science and AI in Battery Production

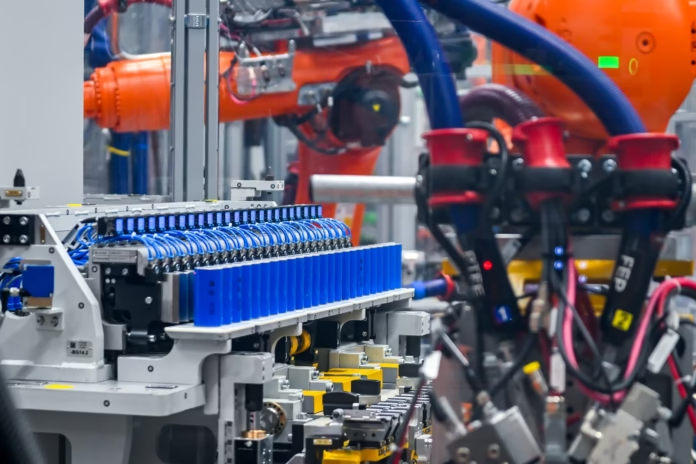

Patrick Zimmermann, a data scientist and IT project manager at BMW, exemplifies the vital role of AI and data analytics in high-voltage battery manufacturing. He leads an interdisciplinary team handling the entire data flow—from capturing manufacturing data on the shop floor to transforming it into intelligent insights via cloud-based analytics. By implementing the Industrial Internet of Things (IIoT), BMW enhances production visibility and responsiveness. This integration supports continuous quality control using AI-based inspections, reducing defects and optimizing processes. Such AI-driven analytics are critical for managing the new cylindrical round cell design and novel manufacturing workflows in the Gen6 battery.

A Groundbreaking Project with End-to-End Digital Solutions

What makes BMW’s Gen6 battery project stand out is its complete digital ecosystem approach. Zimmermann highlights the zero-defect production philosophy, powered by continuous data processing and visual data analysis from manufacturing equipment. The team uses OPC UA interface technology to connect plants digitally, creating standardized digital twins that replicate physical processes in real time. This consistent IT infrastructure across global production sites allows BMW to deploy uniform analysis dashboards, swiftly identifying improvement areas. The ease of transferring these AI-based dashboards from pilot to series production underscores the efficiency of this digital approach.

Advantages of New “Greenfield” Plant Construction

BMW’s decision to build new assembly plants for the Gen6 batteries on greenfield sites rather than upgrading existing facilities offers distinct IT advantages. Zimmermann explains how designing these facilities from scratch frees the IT architecture from legacy constraints. This freedom enables the adoption of the latest IIoT and AI innovations on a large scale. The new, purpose-built factories foster an optimized layout for digital integration—enhancing data flow, analytics, and overall operational performance. This forward-looking strategy creates a blueprint for future EV battery manufacturing worldwide.

BMW Leading the Future of EV Battery Production

BMW Group’s pioneering use of data science, AI, and the IIoT in manufacturing next-generation high-voltage batteries exemplifies the future of electric vehicle production. By combining deep technical expertise with an innovative digital infrastructure, BMW optimizes quality, efficiency, and scalability across global plants. The Gen6 battery not only advances the core technology of EVs but also demonstrates how digital transformation drives automotive manufacturing forward. This integration ensures BMW remains at the forefront of electric mobility, delivering enhanced performance and sustainability to customers worldwide.