A Technological Leap for High-Voltage Electric Vehicles

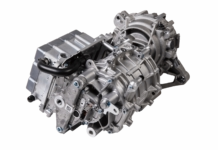

As electric vehicles (EVs) rapidly evolve, the demand for efficient and durable powertrain components grows alongside. One such component is the e-Axle, an integrated electric drive system critical to modern EV propulsion. These systems operate under high-voltage conditions that can cause electrical pitting in bearings. A form of damage that results from current leakage. To meet these emerging challenges, NTN Corporation has introduced a cutting-edge solution. The Resin Mold Insulated EV Bearing, specifically designed to withstand high-voltage EV environments and improve long-term performance.

Advanced Bearing Technology Minimizes Electrical Pitting

NTN’s new bearing uses an injection-molded resin insulation layer to prevent current from entering the bearing. This layer is applied to the outer diameter and width surfaces of the bearing. This achieves insulation resistance greater than 1,000 volts. This high level of resistance effectively reduces electrical pitting, a common cause of noise, vibration, and failure in EV e-Axles. With EV battery voltages expected to rise to 800 volts and beyond, such insulation becomes crucial for extending the operating life of powertrain components.

Superior Durability for Harsh Operating Conditions

The resin material and molding process used in NTN’s insulated bearing are engineered for strength and thermal stability. Differences in thermal expansion between metal and resin can lead to cracking, but NTN’s proprietary formulation resists these stresses. The result is a robust and reliable bearing that maintains structural integrity across a wide temperature range, therefore ensuring long-term operation even under severe environmental conditions common in electric vehicle systems.

Supporting the Next Generation of EV Powertrains

The Resin Mold Insulated Bearing has already been adopted by overseas EV manufacturers. Its success lies in NTN’s ability to tailor solutions based on specific vehicle operating conditions. The product’s high insulation and mechanical durability have earned it strong evaluations, leading to mass production. As the global EV industry shifts to higher-voltage platforms, this bearing plays a pivotal role in ensuring drivetrain longevity and minimizing downtime.

Continuing Innovation in Electric Vehicle Applications

Looking ahead, NTN plans to expand its lineup of electrical pitting-resistant bearings, including conductive bearings equipped with rubber seals. The company is also investing in research to better understand electrical damage mechanisms and to develop predictive models for bearing life in high-voltage environments. NTN will showcase these innovations at the Automotive Engineering Exposition 2025 in Yokohama, highlighting their ongoing commitment to supporting the electric mobility revolution with state-of-the-art bearing solutions.