A Technological Shift Toward Greener Electric Vehicles

The rapid evolution of electric vehicles (EVs) demands technological innovations that improve both performance and sustainability. One major concern in EV manufacturing is the use of rare earth elements, which are expensive and environmentally taxing to source. Manufacturers typically use these materials in motor magnets to help them withstand high temperatures. However, a groundbreaking advancement by Continental may significantly reduce this dependency. The introduction of the e-Motor Rotor Temperature Sensor (eRTS) sets a new standard in rotor heat monitoring for electric motors. This sensor directly measures rotor temperatures with unmatched precision. This provides automakers with greater flexibility in motor design while also cutting down on rare earth material usage.

Precision Sensor Technology for Superior EV Motor Control

Continental’s eRTS sensor is the first of its kind to measure rotor temperature directly within permanently excited synchronous motors in EVs. Traditional systems rely on software algorithms that estimate rotor heat using external measurements, resulting in a high tolerance margin of up to 15°C. The eRTS dramatically narrows this gap to just 3°C, giving manufacturers precise data to optimize motor design. This accuracy reduces the need to overcompensate with heat-resistant rare earth magnets, resulting in more sustainable and cost-effective production. It also opens new opportunities for improving EV motor performance, as engineers can safely push the operating limits of their designs with confidence.

Driving Sustainability Through Innovation

The eRTS not only improves temperature control but also exemplifies how smart sensor design contributes to sustainability. By minimizing rare earth element usage, the technology supports a more responsible EV supply chain. This is increasingly vital as global demand for electric vehicles continues to grow. Additionally, the sensor integrates seamlessly with other Continental technologies, such as the e-Motor Rotor Position Sensor. When used together, these devices form a synergistic system that improves overall vehicle efficiency and reduces manufacturing complexity.

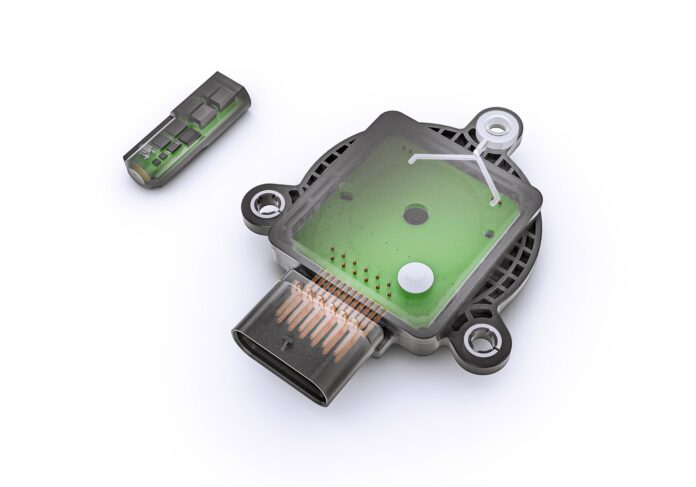

How Continental’s eRTS Sensor Works

At the heart of this innovation is a two-part system using Piezo ultrasound for communication and power. The “mote” component, located near the motor magnet, collects temperature data. It is wirelessly powered by the “transducer,” which is mounted externally on the chassis and connected to the EV’s control system. This design eliminates the need for internal wiring and enhances system durability. With this setup, the eRTS delivers real-time temperature data with minimal energy use. As part of Continental’s expanding e-Mobility Sensors product line, the eRTS is positioned to become a key technology in the shift toward smarter, cleaner electric transportation.