In addition to batteries and electric motors, Volkswagen is now also developing pulse inverters and thermal management systems in-house. Volkswagen hopes to achieve significant efficiency and cost advantages by providing the drive systems from a single source. The company states that an efficiency of more than 20 percent is possible through an optimal combination of individual components alone.

At Tech Day 2023, Volkswagen Group Technology presented an outlook on future electric vehicles in the areas of batteries, charging systems and electronic components. The company’s main focus was on future electric drive systems. The size of the group and the experience it has enables us to take advantage of the huge economies of scale, which benefits customers and enables us to build even better vehicles, says Oliver Blume of the Volkswagen Group. The company, which aims to be a technological leader in the field of electric mobility, relies on its internal resources.

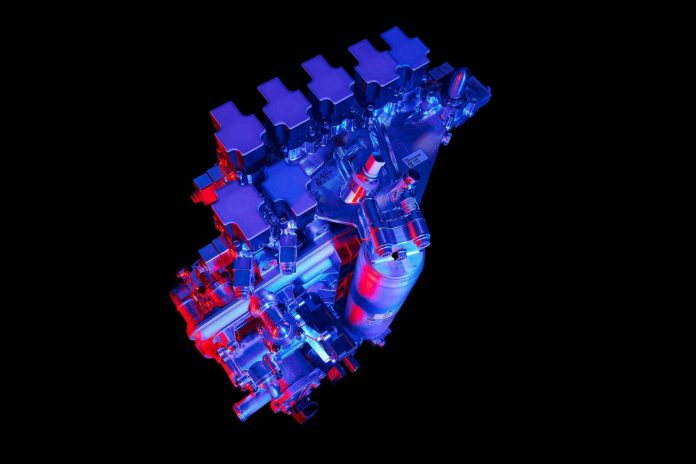

Pulse inverters, the brains of electric drive systems, are largely responsible for efficiency and performance. In the pulse inverter developed by Volkswagen for the first time, hardware and software were designed from scratch. It is stated that it has been developed with a modular principle so that it can be used in from entry-level engines to sports cars with powers up to 500 kW in the future.

On the thermal management systems side, a very compact, integrated thermal module is said to replace existing systems. The system in question will control all ventilation, including the battery, which will have a significant impact on the distance and ultra-fast charging capacity of the vehicles. The all-in-one module is also lighter, more durable and more efficient.